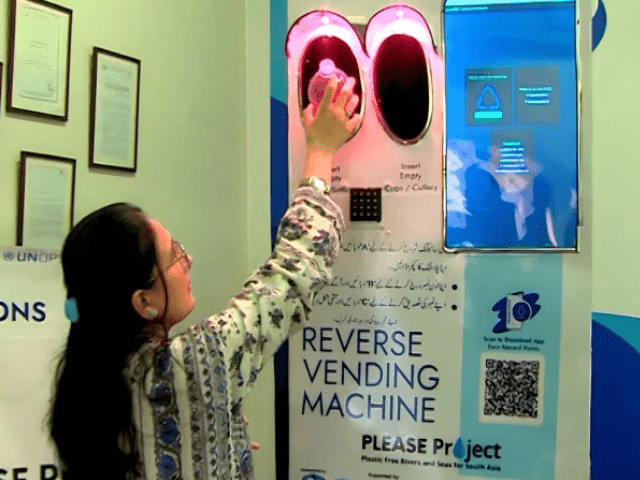

A new ecological initiative has been launched in Lahore aimed at addressing plastic pollution by encouraging citizens to recycle used plastic bottles, it emerged on Monday.

According to the program, residents can deposit empty plastic bottles in reverse vending machines (RVM) and win up to RS1,000 in “Green Credit” per kilogram of plastic, approximately 20 bottles of a liter and a half.

The project, led by the ISP environmental solutions with the support of the Intratch group and the World Bank, is part of the Green Credit Program of the Punjab Environmental Protection Agency. The project aims to transform how urban waste is managed and perceived by offering financial incentives in exchange for the plastic used.

LAHORE produces around 500 tons of plastic waste daily, much of which pollutes river routes and landfills, according to the president of the Intratch group, Gulfam Abid.

“These new reverse vending machines will collect single -use plastic items, including bottles, cups and plates,” he explained. “The collected material will be reused in raw materials for paths, environmentally sustainable road repairs and bricks.”

Read: Cut Rate about chemicals, Stokes plastic concerns

Each RVM is capable of storing up to 25 kgs of plastic and is equipped with sensitive weight sensors that non -plastic materials reject. Users simply insert the bottles into a designated slot, press the “A” button, enter your mobile phone number and press the “B” button to see your credit data on the screen. You can also access the same information through a dedicated mobile application.

The application not only tracks credit, but also connects users directly with waste distributors. Citizens can sell their plastic through the platform, and the company’s representatives will collect the items of their location. More than 18,000 local scrap dealers have been incorporated into the system, and they can also obtain green credit in addition to their regular profits.

In the initial phase, the machines are being installed in four private universities in Lahore. Later, the project will expand to public and private spaces.

While machines are manufactured locally in Pakistan, they incorporate advanced Chinese technology. Each unit costs around RS800,000 to produce.

An “ecological brick plant” has also been established in the Sucal Industrial Heritage as part of the program. It will manufacture construction grade bricks using the collected plastic. The inauguration of the plant is scheduled for July.

The officials emphasize that the project goes beyond only installing machines, its broader objective is to instill a sense of environmental administration among the public. “We want people to see plastic not as waste, but as a valuable resource that can be reused to obtain environmental and economic profits,” said an official.