- Harvard Engineers Created Robotic Muscles Using Multi-Material Rotational 3D Printing Techniques

- Hollow polyurethane tubes filled with air or fluid allow for pre-programmed movement.

- A spiral actuator deploys while a gripper curls fingers around objects.

A team of Harvard engineers has developed a 3D printing technique that allows fully flexible structures to twist, bend or lift as needed, creating what researchers describe as robotic “muscle.”

The method, called multi-material rotational 3D printing, combines several printing methods and allows for the simultaneous deposition of multiple materials through a single nozzle that rotates continuously while printing.

This allows precise control over how the materials interact, producing hollow tubes that can be pressurized to generate movement in a pre-programmed way.

How the printing method works

The technique uses a strong outer layer of polyurethane to protect an inner gel-like polymer called poloxamer.

Once printing is complete, the inner gel is removed to leave hollow tubes that act as actuators capable of rotating or bending when filled with air or fluid.

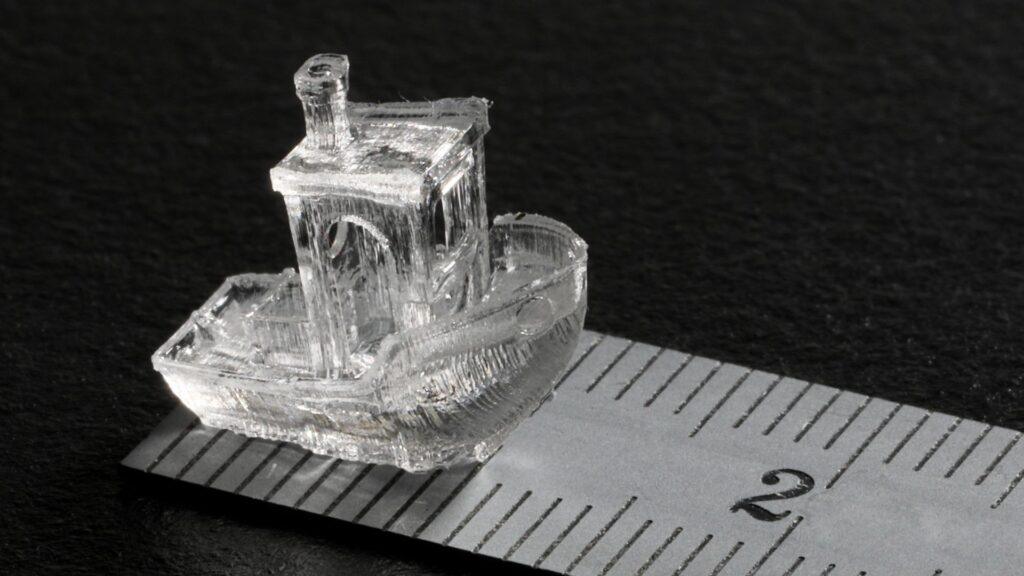

The researchers demonstrated the process using a spiral flower-shaped actuator that unfolds when inflated and a hand-like gripper capable of curling its fingers around objects.

Nozzle design, rotation speed and material flow are calibrated to determine exactly how the printed structure will move, allowing movement logic to be integrated directly during printing.

Traditional soft robotics requires casting individual components and assembling them layer by layer, a laborious and time-consuming process.

In contrast, this 3D printing method can produce a complex and functional structure in a single print, with movement logic encoded in the material itself.

The approach has potential implications for industrial-scale production, potentially reducing both the time and cost in creating malleable robotic structures.

Researchers suggest that, if successfully scaled up, it could accelerate innovation in everything from prosthetics to underwater construction.

But here’s the scary part…these robots could manipulate objects in industrial or crowded environments, causing accidents if they fail or behave unpredictably.

Widespread adoption of these highly adaptive robots in workplaces could also accelerate job losses or even major industrial accidents if not properly controlled.

These scenarios show why some may consider the breakthrough’s capabilities slightly terrifying.

While the progress is impressive, the speed and simplicity of this method raise questions about long-term safety and monitoring.

There are also concerns about the ethical use of programmable robotic muscles in human-adjacent environments.

Published in Advanced materialsThis technique is now subject to a patent filing, but until it is successfully applied on an industrial scale or in environments where human interaction is involved, its practical impact and potential risks remain uncertain.

Follow TechRadar on Google News and add us as a preferred source to receive news, reviews and opinions from our experts in your feeds. Be sure to click the Follow button!

And of course you can also follow TechRadar on TikTok for news, reviews, unboxings in video form and receive regular updates from us on WhatsApp also.