- ANKER EUFYMAKE E1 prints textures up to 5 mm thick using UV curable ink, no filament

- More than $ 45 million collected in Kickstarter makes the E1 the most financed project to date

- EUFYMAKE E1 admits more than 300 materials, including metal, leather and curved surfaces

Anker’s last incursion into creative tools has unexpectedly taken Kickstarter with his new device, the Eufymake E1, which generates almost $ 45 million in promises with days still left in his campaign, which makes him the most financed Kickstarter project to date.

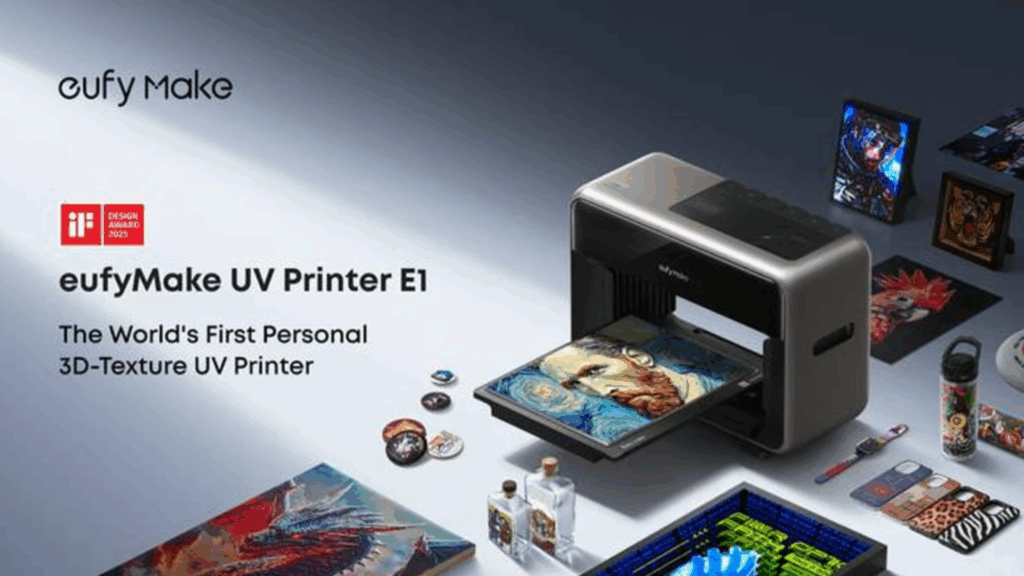

Developed under the EUFY of Anker, E1 is marketed as the first 3D 3D texture UV printer.

While emotion among sponsors is undeniable, the real question is whether this 3D printer machine all in one can fulfill its extraordinary promise.

A different version of 3D printing at home

Unlike a typical homemade 3D printer, the Eufmake E1 does not work with the filament to build objects; Instead, use UV curable ink and a process that Anker calls AMASS3D technology to overlap ink in textured designs on flat or curves.

Textures can reach up to 5 mm thick and can be printed in more than 300 materials, including glass, leather, metal and wood.

It also admits cylindrical objects through rotary printing and direct exit to the film to make personalized stickers.

From a technical point of view, the E1 is full of features, including laser leveling, an 8 MP camera with AI positioning and the colormaestro system that offers vivid and lasting impressions in full color.

The company also promises a sleeveless user experience, thanks to the Jetclean self -limp system.

These extras could attract fans to fans and small businesses equally, especially those that produce personalized goods such as ornaments, vessels or vinyl stickers.

Even so, this is not just an intelligent manufacturing tool; It is clearly positioning itself as an important launch for the DIY market.

With the euphmake e1 pointing to the consumer space, questions about long -term durability, ink costs and real world precision, factors that often separate a device from a reliable tool arise.

Low operational claims, such as “an ink dollar in a personalized metal sign” may sound convincing, but must be tested outside of promotional videos.

Ink consumption is a significant consideration for 3D printers. While the Eufmake E1 campaign claims 600 ml produces about 1,000 small impressions, there are no detailed ML data due to printing for the 3D output.

Taking into account that, according to reports, an ink set costs around $ 299, this means that an average user could spend about $ 0.50 per print, and possibly more depending on the application, already long term, it could be too expensive for small businesses.

Users looking for the best printer for daily use or even the best laser recorder for customization of materials may need to carefully compare before compromising.