- Chemical -free recycling admits supply landfills and chemical cuts

- Recovered materials admit electric cars, wind energy and advanced electronic manufacturing

- The sustainable plan of the end of life redefines the future for storage in US data centers.

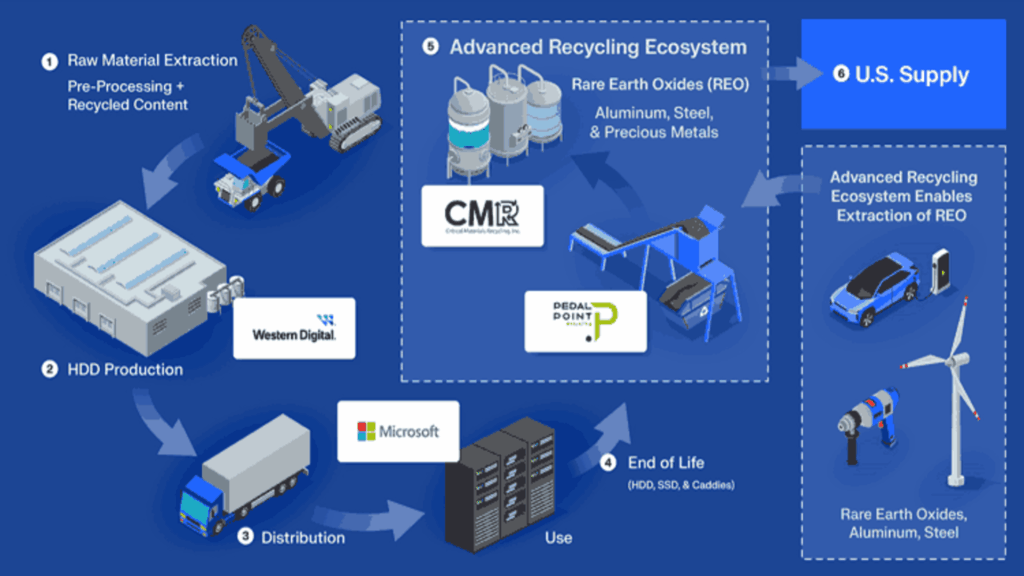

A new Microsoft and Western Digital pilot program has demonstrated a new recycling method of rare earth elements (REE) of the dismantled hard disk units.

The initiative, developed in collaboration with the recycling of critical materials (CMR) and pedal point recycling, successfully recovered almost 90% of rare earth oxides and around 80% of the total mass of raw material of end -of -life units and related components.

Using materials obtained from Microsoft headquarters in the United States, the project processed approximately 50,000 pounds of grated HDDs and assemblies, making them high purity elementary materials. Now they can be reused in key sectors such as electric vehicles, advanced wind energy.

The old HDD now have more value

The project uses a recycling process without acidic and environmental respectful that reduces greenhouse gas emissions by 95% compared to conventional mining and refining.

This approach not only recovers rare earths such as neodymium, proaseodimium and disposium, which are essential for HDD magnetic systems, but also extract valuable metals that include copper, aluminum, steel and gold, feeding them again in the US supply chain. Uu shows that even external hard drives can have a second ecological life.

Despite the critical role of rare earths in cloud infrastructure, current national recycling efforts in the United States recover less than 10% of these materials.

Meanwhile, more than 85% of Ree’s world production remains concentrated abroad, but this pilot aims to change that, offering a scalable and domestic solution that reduces landfill waste, improves the resilience of the supply chain and reduces the dependence of foreign sources.

“This is a tremendous effort of all parties involved. This pilot program has shown that the management of the end of life (EOL) sustainable and economically viable for HDDS can be achieved,” said Chuck Graham, corporate vice president of cloud supply, supply chain, sustainability and safety in Microsoft.

The recycling of solution without acid (ADR), a technology developed at the Critical Materials Innovation Center (CMI), was fundamental for this achievement.

“This project is significant because the HDD raw material will continue to grow worldwide as AI continues to boost the demand for HDD data storage,” said Tom Achieveasso, director of CMI.

Through Storage pocket